Introduction The humanoid robotics revolution is accelerating at an unprecedented pace. With major tech companies investing billions in bipedal machines…

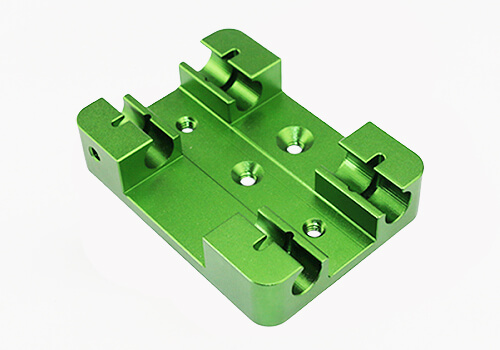

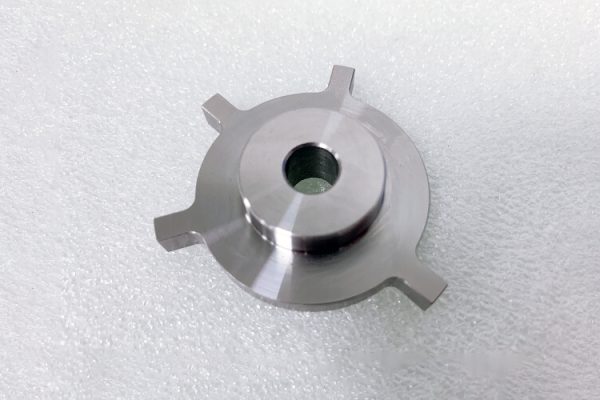

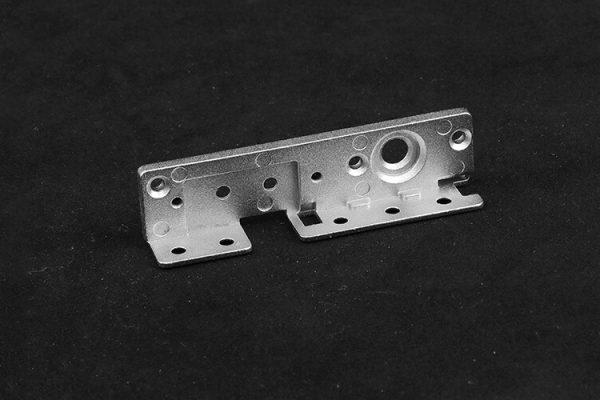

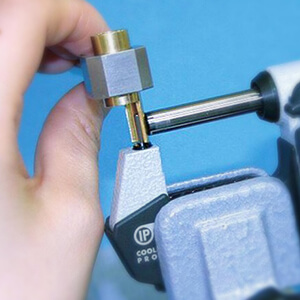

Best Parts is a professional online CNC machining service supplier in China. Founded in 2002. Our plant area has already exceeded 6000㎡. We Started as prototype and OEM parts manufacturing in the year of 2002 by CNC machine. With the capabilities of CNC Machining, CNC turning, CNC milling, SWISS CNC precision machining, Die casting, Finishing and assembly etc.. Best parts provides online one-stop service from parts design,instant quote to rapid prototyping and mass productions…